Gossip

Do you understand the Cutting of Custom die cut boxes?

The world is making new advancements in every race of life, and packaging and printing have evolved. Adopted advanced techniques like die-cut boxes, UV lamination, Pearl coating, and many more have made product packaging attractive and functional.

What is Die-cutting and its use?

As the name shows, die cutting is a process of converting different types of material or boards into customized shapes with advanced and complex machines. These high-quality machines ensure that the shape, which is cut out, must be customizable according to the client’s required die-cut boxes. This process makes the printing process kind of a masterpiece with constant professional supervision.

Die is a metallic tool installed in machinery that performs the die-cutting process quite fatly with minimal mistakes chances. These machines are specially designed to cut massive quantities of fabric or paper in the required shapes and sizes in less time. Every time you can experiment with unique shapes and designs, however, these patterns are drawn with thick colorful lines to highlight the required operational area. Companies who want to share their customized giveaways or souvenirs are fond of custom die-cut printed boxes. They are also the best choice for sharing promotional or business gifts with printed logos and personalized messages.

Consider different types of die-cutting processes

Different kinds of die-cutting processes ensure the best result with exact quality work. However, you can choose the best suitable according to your vision and your product requirements. Some of the most popular methods are hereunder:

Blanking: Slicing the exterior edges of flat material is called blanking. In this process material, look flatter than its original shape,

Drawing: While drawing can pull the material through the machine to a specific length. This type of cut works best for elongated products with small girths.

Forming: This kind of die-cutting is done on a curved surface. It is mostly used to create cylinder style.

Broaching: It requires the use of multiple large rows of cutting teeth to carve the material. That is usually too hard to deal with only steel die.

Coining: As its name shows, coin-shaped holes are punched into paper sheets, and applied pressure through machines. To create meticulous and intricate designs.

As we have seen with the help of process description. You can apply any kind of technique to create a mesmerizing die-cut paper box according to your product requirements. However, there are some further more advanced procedures to assist you in making your brand staple custom packaging insignia. Like Flatbed die cutting, rotary and semi-rotary die cutting, steel-rule, and many more.

Multi-functional use of laser in die cutting for accuracy

After the intervention of a laser, the process of making Kraft die-cut boxes becomes effective and accurate. These cookies like cutting machines prepare the same patterns cut from any kind of material more efficiently.

A packaging outline is generally designed and created by CAD (Computer-Aided design). That allows digital die-board transfer to wooden die-board for giving you perfectly lined and precise outlines. With the intervention of laser cutters, the accuracy and precision go sky-high.

The function of Cutting Plates or Pads

Cutting plates or cutting pads are due-cut sandwich sort processing for creating design through assembling materials. Through the help of this process, you can get the required astonishing results in your packaging and display collectively.

For effective functionality of die-cutting machines, these plates or pads need to be changed promptly otherwise they will wear down. Effective designing and execution of cutting can improve the printing process because with efficiency you can create marvelous die-cut printed boxes.

Customize your metal dies

If you are thinking about out-of-the-box custom die-cut box printing with an exclusive design, you can also make your metal die-cut modes. Yes, technically you can execute this for some creative idea display. However, it is a difficult process so leave it to a professional packaging and printing company to help you create the unusual shape of your custom packaging. It is best to take benefits from experts in the market that can help you complete your dream with specialized machines and processing.

The finishing touches to make something ravishing

We have found out that with the help of the die-cutting process, it’s no wonder that you can create a unique and great-customized packaging experience. For producing custom premium packaging, the use of this procedure ensures high-end sophisticated die-cut boxes with a luxury feel. Several finishing techniques can elevate your box packaging experience. These are:

- Embossing/Debossing

- UV Printing

- Foil stamping

- Pearl Coating

With the effective use of these lamination techniques, your die-cut printed boxes become accurate and can be repeated without any error. It makes room for creating a great retail packaging solution.

Benefits and reasons for adopting the Die-cutting packaging technique

With the use of an amazing die-cutting process, advanced machines, and diversified styling, companies can get the maximum benefit from their die-cut printed boxes. With these attractive features, your custom packaging can become standardized with better benefits. You can apply this technique to any sturdy and strong material, for a long-lasting effect in the retail market.

Easy customization becomes possible

Die-cut boxes are multi-functional and can be customized with high-quality printing and advanced finishing and lamination. Manufacturers can openly play with the shape and size of their custom packaging with custom die-cut box printing. Multicolor printing, image transferring, enterprise trademarks, or logo printing become creative tasks.

Brand awareness through packaging and printing

With the use of advanced customization, brands use these die-cut paper boxes for creating strong brand awareness in the retail market. Because custom packaging boxes provide the best opportunity for enhancing brand awareness by Premier Custom Boxes. Effective marketing and advertising with printed logos, trademarks, and company information become very impressive.

Lightweight attribute

Die-cut boxes are strong and sturdy with a lightweight attribute. Created from cardboard base material made they are lightweight due to their quality, cost of shipping and transportation decreases drastically.

There are endless further benefits of die-cut boxes to increase your business revenue with an attractive packaging style. You can adapt the material and technique according to your needs and customization requirements in a cost-efficient manner.

Gossip

Where can I buy my luxury wedding shoes at the best price?

When it comes to your wedding day, one of the most important parts of the whole affair is making sure you have the perfect bridal look. From the dress to the accessories, everything should be perfect to ensure you feel beautiful and confident on your special day. And one of the most important accessories of all is the perfect pair of wedding shoes.

All about Luxury wedding shoes

Wedding shoes don’t just have to be functional, but should also make a statement, and luxury wedding shoes are the way to go if you want to make a statement. Luxury shoes look beautiful and are made from the highest quality materials, making them perfect for your big day. Whether you are looking for something traditional, or something more modern, there are plenty of wedding shoes to choose from.

When it comes to luxury Bridal shoes, there are several things to consider. Firstly, you should think about the style of the shoes. Do you want something classic, timeless, or more on-trend and fashion-forward? Secondly, think about the color of the shoes. Do you want something in a neutral hue, or something a bit brighter and more eye-catching? Lastly, think about the heel height. Do you want something with a low heel or something with a higher heel?

Once you have decided on the style, color, and heel height of your luxury wedding shoes, it’s time to think about the materials used. Wedding shoes are often made from luxurious materials such as silk, satin, velvet, and even leather. These materials are often embellished with beads, sequins, and crystals to give them an extra special touch.

Luxury wedding shoes are an essential part of any bride’s bridal look and can make all the difference in creating the perfect look on your big day. With a wide variety of styles, materials, and heel heights to choose from, it’s easy to find the perfect pair of luxury wedding shoes to complete your bridal look.

Purchasing luxury wedding shoes at the best price might be difficult due to the high-quality materials and expertise involved in their manufacturing. There are, however, a number of ways to save money and get fantastic prices on luxury wedding shoes:

Shop during sale seasons: Most luxury shoe brands have seasonal sales where you can get discounts on their products. You can join their newsletters to receive notifications when their sales begin.

Shop at outlet stores: Many luxury companies have outlet stores where their products are sold at reduced prices. You can look for an outlet store near you or shop online.

Online shopping: Internet merchants such as Net-A-Porter, Farfetch, and Saks Fifth Avenue provide a diverse range of products.

Keep an eye out for sales and specials, and compare costs from several retailers before making your final decision. You no longer need to worry about anything because there are still many questions. You may find all of your questions answered here.

Top International Luxury shoe brand

For my wedding shoes, which brand do I need to think about? Below, I’ve compiled a list of some of the top designer shoe brands for weddings, whether you’re searching for something classy and traditional or hip and modern. Enjoy your shopping!

Freya Rose is a luxury wedding shoe brand for brides and bridesmaids. Founded in 2010, Freya Rose has become one of the leading bridal shoe brands in the UK. With an eye for detail and luxurious materials, Freya Rose creates unique handmade wedding shoes that make every bride feel special on their big day. The brand offers a variety of styles from classic court shoes to modern wedges and sandals. Each pair is handcrafted using the finest leather and fabric materials, making them comfortable and stylish for the perfect look. Freya Rose shoes are available in a range of sizes and colors to suit every bride’s individual style.

Jimmy Choo: Best known for their luxury designer shoes, Jimmy Choo has a variety of stunning wedding shoes to choose from, such as traditional pumps, stylish sandals, and trendy ankle boots.

Manolo Blahnik: Manolo Blahnik is another high-end designer shoe brand that offers a choice of exquisite bridal shoes in a variety of colors and styles.

Badgley Mischka: Specializing in formal and bridal footwear, Badgley Mischka has a large assortment of stunning and dazzling shoes for your wedding day.

Stuart Weitzman: Stuart Weitzman offers a wide range of elegant and comfortable shoes, including traditional pumps, sandals, and trendy boots.

Nina Shoes: Nina Shoes are a popular alternative for economical and attractive shoes, including traditional pumps, sandals, and wedges.

Gossip

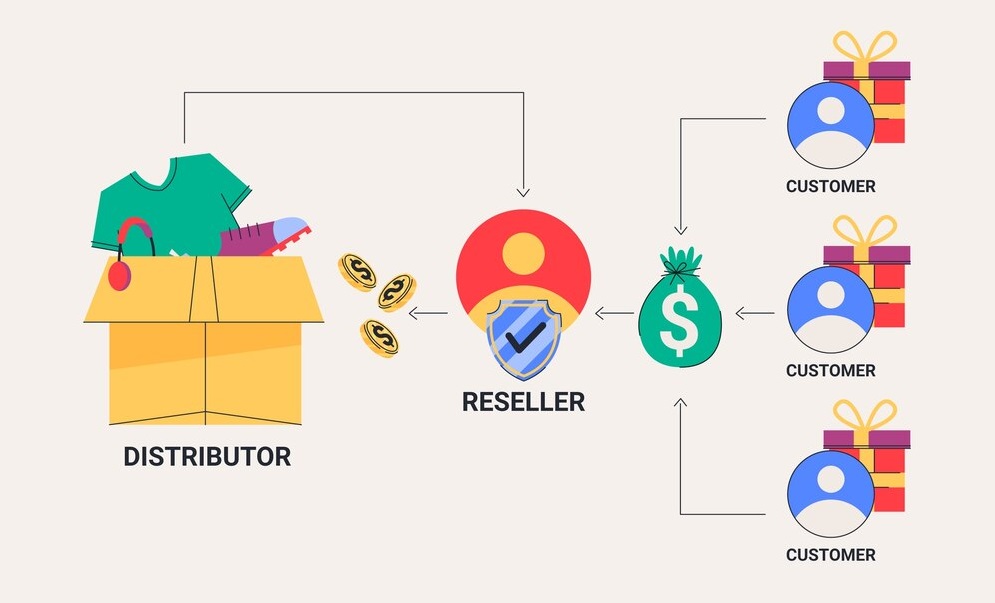

How to Be Successful In Retail Market?

There are several key strategies that can help you be successful in the retail market:

Offer a High-Quality Product or Service

Offering a high-quality product or service mean that the product or service meets the customer needs in terms of staging, features, and advantages. This can include using high-quality materials and components, ensuring that the product or service is reliable and effective, and providing excellent customer support.

To offer a high-quality product or service, a business needs to be dedicated to continuous improvement and innovation. This may involve investing in research and development, implementing new technologies and processes, and regularly ask for feedback from clients to recognize areas for development.

In addition, a business that offers a high-quality product or service is possible to have satisfied customers who are willing to recommend the product or service to others. This can lead to positive word-of-mouth advertising and can help to create the business honor and customer base over time.

Eventually, offering a high-quality product or service is essential for the success of any business, as it helps to differentiate the business from its competitors and can guide to increased sales and lucrativeness.

Understand Your Target Market

Drip your target market is an essential side of running a successful business. A target market is the specific category of consumers that a business is struggling to reach and sell its products or services to. Understanding your target market involves knowing their needs, preferences, and behaviors, and tailoring your products or services to meet those needs.

To understand your target market, it is important to conduct market research. This can include gathering data through surveys, focus groups, and customer interviews, as well as analyzing industry trends and opponents. By collecting this info, you can gain a huge understanding of your target market’s cohorts, values, and buying habits.

Having a clear understanding of your target market can help your business to develop effective marketing strategies and make informed decisions about product development and pricing. It can also help you to identify potential challenges and opportunities, and adjust your business replica correctly.

In the end, understanding your target market is crucial for the success of your business, as it allows you to create products or services that meet the needs and demands of your customers, and to successfully communicate the worth that you offering to them.

Develop a Strong Brand

Developing a strong brand is an important aspect of making & growing a successful business. A brand is the overall perception that customers have of a company and its products or services. It encompasses elements such as the company name, logo, values, and mission, as well as the look and feel of its marketing materials and customer experiences.

A strong brand can help a business to extend from its opponents and build a true customer base. It can also help to build trust and credibility, as customers are more likely to do business with a company that they remember as reputable and reliable.

To develop a strong brand, a business needs to be compatible in its messaging and visual identity, and provide a high-quality product or service that meets customer needs and assumption. It is also important to regularly communicate with and listen to customers to understand their needs and liking, and to modify the brand accordingly.

Investing in branding efforts, such as creating a professional website and engaging in social media and other marketing activities, can also help to build brand awareness and reach a wider audience.

Overall, a strong brand is an invaluable asset for a business, as it can drive customer loyalty, increase sales and profitability, and differentiate the business in a crowded market.

Have a Customer-Centric Approach

Having a customer-centric approach means that a business focuses on the needs and preferences of its customers and puts them at the center of its operations. This involves putting in place processes and systems that ensure that the customer experience is positive and that customer needs are met in a timely and effective way.

A customer-centric approach can involve offering personalized products or services, providing excellent customer support, and regularly ask for estimation from customers to pick out areas for enhancement. It may also involve using customer data and analytics to better understand customer behavior and preferences, and to make informed decisions about products, services, and marketing efforts.

Adopting a customer-centric approach can help a business to build strong relationships with its customers, increase customer satisfaction and loyalty, and drive sales and profitability. It can also help a business to stand out from its competitors and differentiate itself in the market.

Overall, a customer-centric approach is essential for the success of any business, as it authorize the business to understand and meet the needs of its customers and create a positive and valuable customer experience.

Use Effective Marketing and Advertising

Using effective marketing and advertising is an important aspect of building and growing a successful business. Marketing refers to the activities and strategies that a business uses to promote its products or services and reach its target market. Advertising is a specific type of marketing that involves creating and placing ads in various media channels, such as television, radio, print, and online.

Effective marketing and advertising can help a business to build brand awareness, generate leads, and increase sales and profitability. It can also help to differentiate the business from its competitors and begin it as a leader in its industry.

To use successful marketing and advertising, it is important for a business to have a plain understanding of its target market and to make marketing and advertising news that resonate with that audience. It is also important to select the right marketing channels and to track and analyze the results of marketing and advertising attempt to identify areas for refinement.

In addition to traditional marketing and advertising methods, custom logo packaging boxes can also play a role in effective marketing. Packaging is the process of designing and producing the container or wrapper that a product is sold in. Effective packaging can help to differentiate a product on the shelf, attract attention, and communicate key product benefits. It can also influence purchasing decisions and contribute to the overall customer experience.

Overall, effective marketing and advertising, along with well-designed packaging, are essential for the success of any business, as they help to build brand awareness, generate leads, and drive sales and profitability.

Gossip

How many comments did YouTube wipe in three months?

Other ultra-long-haul international flights connecting in the United States include a Delta one from Atlanta to Johannesburg, South Africa …

Now that the federal authorities have arrested Cesar Sayoc in connection with the explosive devices sent to many of those whom Donald Trump rages against as enemies — prominent Democrats, other critics of the President and CNN — some will argue that he is merely a disturbed individual, a lone actor, with no connection to the atmosphere created by the Trump presidency. This is most likely not true.

Yes, Cesar Sayoc appears to be a troubled man. The terror spree he conducted could only be carried out by a person with certain psychological deficits. However, he is not a unique character operating in a vacuum. Cesar Sayocs can be found almost anywhere in America.

[bs-quote quote=”You will never change your life until you change something you do daily. The secret of your success is found in your daily routine.” style=”style-23″ align=”left” author_name=”Darren Hardy” author_job=”American Author” author_avatar=””]

It is this reality that burdens public figures, especially presidents, with the responsibility to use care and caution as they lead the nation. The exception is Donald Trump, whose superheated rhetoric could make himself a factor in the run-up to terror.

Investigators will eventually reveal many factors that could have played a role in the process that led to the mailing of the explosive devices.

Likely Trump’s rhetoric will be just one of many elements. However, denying that it played a role is not an option. Neither can we expect Trump to change.Trump campaigned using taunts and suggestions that all the Cesar Sayocs could have heard as calls to violent action.

When a protester interrupted a rally, Trump announced that he would “like to punch him in the face” and waxed sentimental about the days when protesters would be “carried out on stretchers.”He referenced a “Second Amendment” response to Hillary Clinton’s possible election and offered to pay the legal bills for those who assault his protesters.

The President’s encouragement of violence, combined with rhetoric about the press being “enemies of the people” and political opponents being un-American, are green lights for those who are vulnerable to suggestion. Worse, when you think about the President’s impact on fevered minds, is his penchant for conspiracy theories. With no evidence, he recently suggested terrorists were among immigrants now marching toward the United States.people to believe that almost anything can be true.

Taken together, Trump’s paranoid rants encourage people to believe that almost anything can be true.

Trump allies and fans rejected the notion that he was playing a dangerous game and instead praised his willingness to forgo political correctness and speak plainly. However, this wasn’t plain speech, it was incitement, and the notion that milder rhetoric is somehow less sincere is absurd.Politicians who honor the boundaries of decency and public safety are not mealy-mouthed pleasers. They are normal adults who respect public safety.

As president, Trump never pivoted from his destructive campaign mode to become a leader of all the American people. Just weeks ago, he praised fellow Republican Greg Gianforte for assaulting a reporter who had asked him a question. “Any guy that can do a body slam, he’s my kind of … He was my guy,” said Trump.

-

Fashion7 years ago

These ’90s fashion trends are making a comeback in 2017

-

Entertainment7 years ago

The final 6 ‘Game of Thrones’ episodes might feel like a full season

-

Fashion7 years ago

According to Dior Couture, this taboo fashion accessory is back

-

Politics7 years ago

Illinois’ financial crisis could bring the state to a halt

-

Entertainment7 years ago

The old and New Edition cast comes together to perform

-

Fashion News1 year ago

Fashion News1 year agoGayle King Perspective On Learning From Her Colleagues

-

Business7 years ago

The 9 worst mistakes you can ever make at work

-

Sports7 years ago

Phillies’ Aaron Altherr makes mind-boggling barehanded play